30% off online shopping

China top level motor 220v/380v 3 phase gear motor

dc gear motor with worm gearbox and high torque low rpm

DC Turbine Worm Geared Speed Reducer Wheelchair Brushless Motor

DC Worm Gear Motor 24V DC Gear Box Motor For Electronic

gear motor 6volt motor gearbox 40:1 32mm plnatary gear

planetary gearbox dc gear motor high torque low rpm motors

For Every Occassion

Electrical performance of the geared motors

Low noise, low current, long service life

6mm small DC gear motor

3V voltage DC motor

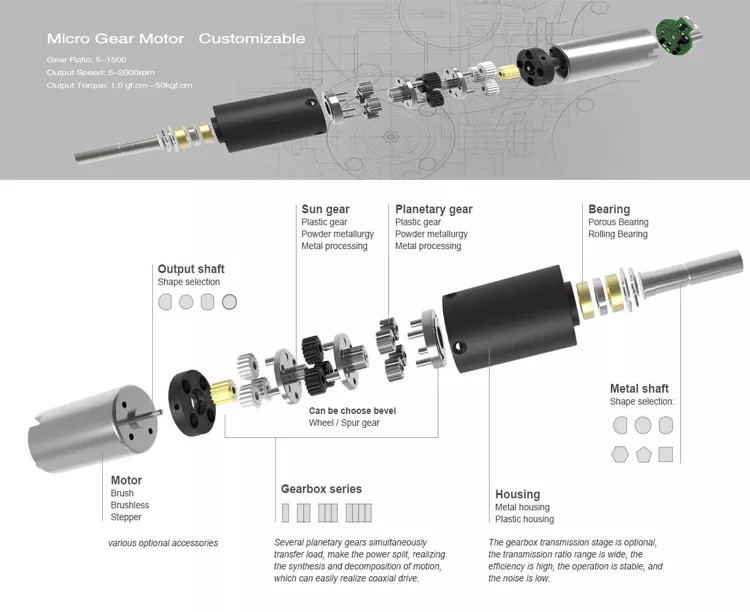

Customization gearbox

Customized electric performance could be achieved on request.

Application

Audio and visual equipment, Household application, Office automation equipment, Automotive products, Toys and models, Medical Application, Electric power tools, Precision instruments, cosmetic tool……

Competitive Advantages

Over ten years experience in manufacturing motor gearbox

Competitive Price

Product Performance: Low noise, High efficiency, Long lifespan

Prompt Delivery: 15 working days after payment

Small Orders Accepted

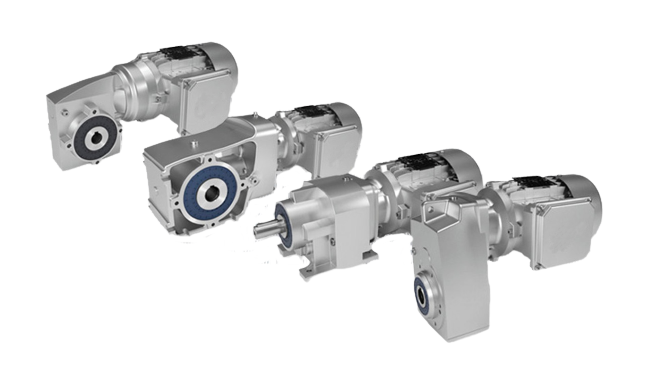

SSJ offers gear motors with brush or brushless motors and either AC or DC configurations. The standard gear motor configurations include:

- Planetary Gear Motors

- Right Angle Shaft Gear Motors

- Parallel Shaft Gear Motors

Our global team of engineers have decades of experience in designing and manufacturing Helical, Spur, Worm, and Epicyclic gears. This assures the optimum gear motor design for many gear motor application.

Gear Motors

How does a geared motor work?

The core function of a gear motor is performed by the gear unit and its gear unit stages and gear pairs. These features transmit the force of the motor from the input to the output. Therefore, the gearing acts as a converter of speed and torque.

In most applications, gearing reduces the speed of the motor while transmitting much more torque than the motor alone can deliver. With this in mind, the design of the gear unit determines whether the geared motor is suitable for light, medium, or heavy loads and short or long periods of energization.

We mean reduction ratio or gear ratio, depending on whether the gear unit reduces or increases the motor’s input speed (called input speed). The ratio I between the input speed and output speed of the reducer is used as a measure for this.

Another critical measurement variable for gear motors is the maximum torque on the output side. This torque is measured in Newton meters (Nm) and is used to measure the force of a geared motor and the load it can move with that force.

Gearmotors

Gearmotors consist of a motor, gear, and bearings in a housing and are commonly used in applications that require a high amount of force (torque) at low speed. DC gearmotors require a battery power source and are used for precise variable-speed applications such as wheelchairs, hospital beds, lifts and medical tables, power seats, and other automotive applications. AC gearmotors operate off an AC power source and are often used in high-power applications, such as lifts, jack, and robotics. Gearmotor accessories like brackets, covers, and extension cables are used to protect, mount, and power gearmotors.

SHop Local

New motor sales

Finding the best value and solutions for your motor needs could sometimes mean acquiring a new motor. We carry only the best in electric motors because of our dedication to high-quality and we will consult with you in delivering the motors you need, when you need them.